CARMOT coating additive in high wear resistant waterborne system

When preparing water-based coatings, engineers often encounter various problems, especially some high-performance coatings pursue extreme balance, some customers pursue the same performance as oil-based coatings, so the research and development of water-based coatings is a more complex process.

You may encounter these problems, which may include the following aspects:

➷Poor appearance, sedimentation, discoloration and delamination of coatings during storage

➷Paint storage deterioration, bubble, thickening, skinning, curing

➷Various problems in production and quality inspection

➷Color derivation problem, Δ E deviation degree

Color is one of the core technologies of paint, paint without color is very monotonous, life without color is boring, so color is very important to us.

Why color problem is difficult to control, the main reason analysis and solutions:

The main reason of the color problem is difficult to control. The main reason analysis and solution are to add the dispersant into the color paste to produce and process the high quality coating. The dispersing agent mainly has the functions of stabilizing pigment from settling, improving grinding efficiency, preventing backroughing and granulating, improving luster and freshness, improving leveling, preventing floating color from blooming, increasing color spreading performance, reducing grinding viscosity of color paste, increasing fluidity.

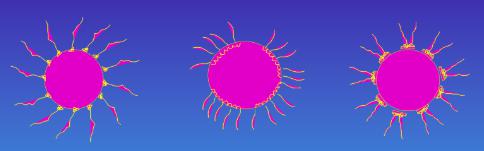

The whole process of pigment paste processing includes wetting, dispersion and stabilization. Schematic diagram of pigment adsorbed by dispersant:

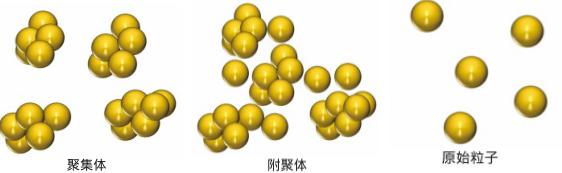

The process of pigment dispersion is that the pigment changes from aggregation state to refinement state. The most ideal state is the extremely refined distribution, and the essence of pigment paste is suspension. Three theoretical distributions of pigment particles:

Polymer dispersants are mainly divided into polyurethane, polyacrylic acid, polymaleic acid and so on. Traditional ionic surfactants are mainly divided into anionic type, cationic type, electroneutral compound and nonionic type。

Reference method for laboratory dispersant evaluation:

1、 Grinding paste

According to the formula, add water, defoaming agent, dispersant, Kwai powder and other auxiliaries in the special container, and mix evenly with the mixer before mixing. After sealing, use the quick hand and the shock machine to grind. When the expected time is reached, the fineness plate is used to detect the dispersion degree of the pigment. When the fineness meets the requirements, the grinding is stopped, and the nylon filter screen is used for filtering before storage.

2、 Testing viscosity

Use viscometer to detect the viscosity of color paste.

3、 Paint mixing

Check the color matching, take out a little of the remaining color paste, and add a certain amount of resin, cosolvent and other additives into the color paste to prepare the color paint. Scratch black and white card to test gloss and covering power.

4、 Detection of color matching

Adjust the remaining paint into different multicolor paint, scrape the black and white card in parallel, and observe the degree of color difference with naked eye in the light box. If there is no color difference, it will be judged as qualified. Place the remaining multicolor paint in the oven, keep it at 50 ℃ for 2 weeks, and retest the color matching property.

5、 Test storage stability

Put the remaining color paste in the oven and keep it at 50 ℃ for 2 weeks. Observe the discoloration, sedimentation, mildew, drying and thickening of the color paste with naked eyes, detect the bottom condition with adjusting knife, measure the viscosity change with viscometer, detect the fineness with fineness plate, and repeatedly detect the color matching and color stability.

6、 arrangement

Clean the tools used in the experiment, sort out the materials used, and improve and save the test records.

7、 Other reference methods

Flow coating test: pour the paint with different dispersants onto the polyester film, and observe the difference of each paint in parallel.

Finger grind test: apply the paint solution of color paste color matching on the base material, grind it several times, and observe the color change degree of the film.

Particle size test: put the color paste sample into the particle size meter, and measure the particle size by the distribution diagram method.

The application of dispersant coating is illustrated by the case of high wear-resistant waterborne coating

I. Experimental background

The coating with special waterborne polyamide resin has high wear resistance, which may produce practical value in high wear resistance.

II. Experimental method

Use dispersant to grind resin free white paste and resin free blue paste, and reserve paint mixing.

III experimental equipment

Multifunctional integrated mixer; Scraper fineness meter; Preparator; Stroke wiping instrument; Gloss meter; Electronic scale; Kwai Fu;

IV experimental operation

The preparation of blue pulp test samples, according to the formula in turn mixed, vibration 2 hours to complete, prepared for standby

| Serial number | Raw material | Quantity wt/% | Model |

| 1 | Deionized water | 44.8 | |

| 2 | Silicone defoamer | 0.3 | CARMOT-F1301 |

| 3 | Dispersant | 19 | CARMOT-Dis2130 |

| 4 | Blue powder P.B. 15:3 | 35 | BGS |

| 5 | PH Regulator | 0.4 | DMEA |

| 6 | Antibacterial agents | 0.5 | B-10 |

| Total | 100 |

White pulp test sample preparation, in accordance with the formula in turn mixed, vibration 1 hour to complete, prepared for standby

| Serial number | Raw material | Quantity wt/% | Model |

| 1 | Deionized water | 25.15 | |

| 2 | Silicone defoamer | 0.15 | CARMOT-F1301 |

| 3 | Dispersant | 3.5 | CARMOT-Dis2130 |

| 4 | Titanium dioxide P.W.6 | 70 | R996 |

| 5 | PH Regulator | 0.2 | DMEA |

| 6 | Antibacterial agents | 0.5 | B-10 |

| 7 | Anti settling agent gas silicon | 0.5 | R972 |

| 100 |

Blue paint test sample preparation, preparation for standby, sample configuration completed, about 5 hours to use up。

| Serial number | Raw material | Quantity wt/% | Model |

| 1 | Polyamide waterborne resin | 90 | PA-100 |

| 2 | Crosslinking agent | 1.8 | F-150 |

| 3 | Silicone Gemini wetting agent | 0.18 | CARMOT-1611 |

| 4 | Blue pulp | 4.5 | |

| 5 | Milky fluid | 4.5 | |

| 101 |

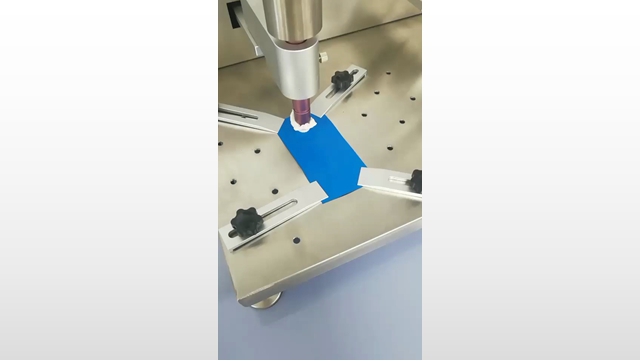

According to the set detection formula, prepare the required raw materials, add the raw materials according to the serial number, stir evenly, set the mixer speed between 500-1200rpm, set the baking temperature at 170 ℃, baking time 5-10min, and the preparator 75-100 μ The wear resistance, viscosity and fineness of the coating were tested.

V experimental data

The dried sample is tested and the following results are obtained

| Wear resistance frequency /1kg | Viscosity η/cps | Fineness /μm |

| 50 times,Traceless | 700 | 20 |

Using the friction cloth, through the 1kg load reciprocating wipe, it is very clear that the coating has high wear resistance( Add rub resistant process video)

VI analysis of experimental results

In the experiment, different dispersant dis 2130 and sample a were used for color paste grinding. Blue paste grinding was more suitable than dispersing agent dis 2130, but the quality of blue paste ground by sample a was poor.

| Serial number | Project | CARMOT-Dis2130 Blue lacquer | Sample A Blue lacquer |

| 1 | Gloss /60° | 87 | 20 |

| 2 | Planeness | Smooth | Rough |

| 3 | Bubble | Nothing | Nothing |

| 4 | Color | Uniformity | Unevenness |

In the experiment, different defoamers were used to control the effect. Carmot-f1301 had a strong defoaming effect。

| CARMOT-F1301 | Sample B | Product C |

| Few bubbles | So many bubbles | Many bubbles |

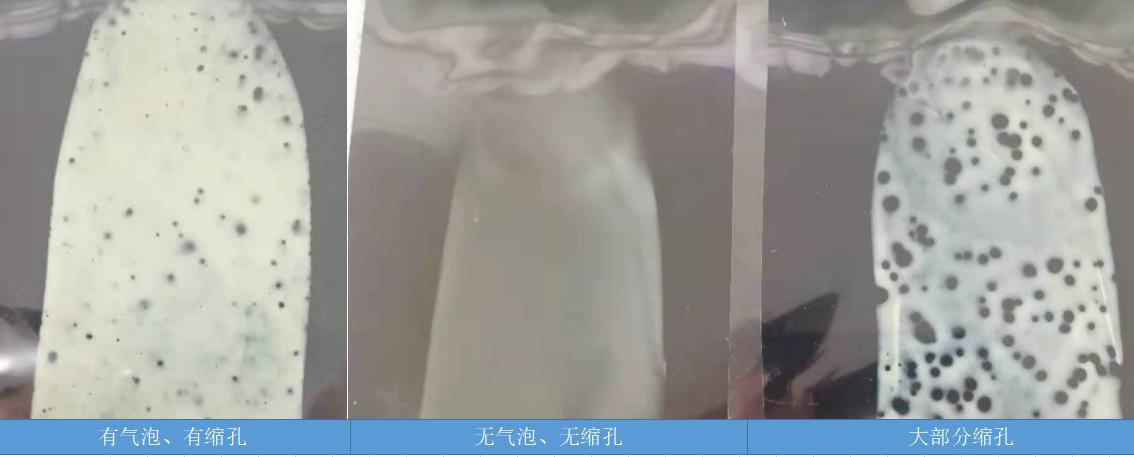

Carmot-1611 has good low foaming property and good wettability of the substrate. Products D, e and f belong to organosilicon type defoamer, products g, h and I belong to acrylic polymer type defoamer, and product J belongs to mineral oil type defoamer.

| Serial number | Defoamer | Effect | Serial number | Defoamer | Effect |

| 1 | CARMOT-1611 | Low bubble, no shrinkage | 5 | Sample G | Shrinkage |

| 2 | Sample D | Shrinkage | 6 | Sample H | Shrinkage |

| 3 | Sample E | Shrinkage | 7 | Sample I | Shrinkage |

| 4 | Sample F | Shrinkage | 8 | Sample J | Shrinkage |

Effect comparison photos(CARMOT-1611 in the middle):

From the experimental analysis, carmot-dis 2130 dispersant has good compatibility with waterborne polyamide resin, and has greater advantages than other types of dispersants such as polyurethane.

Carmot-dis 2130 dispersant also has good dispersion of matte powder in the preparation of water-borne matte coating, which can effectively improve the matte degree.

Carmot-dis 2130 2.5% dosage, laboratory preparation of matting powder has good effect。

| Serial number | Matting agent | Amount of matting agent added wt% | Gloss /60° |

| 1 | TS-100 | 4.3 | 11.5 |

| 2 | 天一105B | 5 | 10.4 |

CARMOT-Dis2130 2.5% dosage was prepared in laboratory, and the same domestic matting powder 105b was dispersed, which had good effect.

| Serial number | Dispersant | Amount of matting agent added wt% | Gloss /60° |

| 1 | CARMOT-Dis2130 | 5 | 10.4 |

| 2 | Sample K | 5 | 10.8 |

| 3 | Sample L | 5 | 9.5 |

CARMOT-Dis2130 Application photos of dispersant and other coatings:

Finally, the process of coating preparation is like stewing spareribs. It's not easy to stew high-quality soup. The effect of dispersant on pigment and filler is just like the seasoning used in stewing soup, which makes a pot of soup full of color and flavor. The use of dispersant makes pigment and filler play a full role. Such coating has higher performance。