Research and Application of PTFE Premixed Slurry

PTFE is a white fine powder, also known as PTFE wax, has good mechanical properties, electrical properties, wide temperature range (-200 + 260 ℃), excellent chemical resistance, weather resistance, and good non-stick, lubricity. The unique structure of PTFE's macromolecule and the extremely high bond energy (460 KJ/mol) between the carbon and fluorine atoms in the molecule make it different from ordinary plastics and give it excellent performance.

Shamrock Technology Corporation(USA) is an innovative leader in the micronized wax and PTFE micronized powder industry, pioneering the use of PTFE micronized wax in inks and coatings in 1960 and providing additional new product development support for dispersions, emulsions and unique submicron products in 2007. 13% of the global PTFE micronized wax market by 2020.

High radiation micronization to obtain the low molecular weight PTFE micronized powder is commonly used in engineering plastics and special engineering materials wear-resistant additives; Emulsion polymerized high molecular weight PTFE micropowder, which becomes fibrous when the thermoplastic flame retardant system is burned, plays a role in flame retardancy and anti-dripping; Nanoscale PTFE micronized powder is used in rubber products to reduce friction coefficient and improve compression change performance.

Ordinary micronized powder is produced by directly polymerizing particles for micropowder grinding. In this paper, We try to use aqueous dispersants to prepare PTFE micronized powder into premixed slurry for use in aqueous coatings and inks to improve the friction performance.

Preparation of polytetrafluoroethylene (PTFE) premix slurry

1.1 PTFE premixed slurry process

Add PTFE micronized powder, water, dispersant, defoamer, wetting agent, thickener, PH adjuster in order in the mixing cylinder, mix for 5-10 minutes, add glass beads (Φ1.0mm) for grinding for 30-40 minutes.

Filter to get uniform PTFE premixed slurry.

| NO. | Raw material | Dosage/% | Process |

| 1 | Deionized water | 50 | |

| 2 | Wetting agent 6001 | 0.5 | |

| 3 | Dispersant | 2.0 | |

| 4 | Defoamer F1301 | 0.8 | |

| 5 | PTFE micronized powder | 50 | Φ3.0cm,600rpm, 5-10min |

| 6 | Thickener 2020 | 1.7 | Add glass beads and grind for 30 minutes |

| 7 | B-10 | 0.1 | |

| 8 | AMP-95 | 0.1 | Adjust the pH to 7.9 |

1.2 PTFE premixed slurry performance

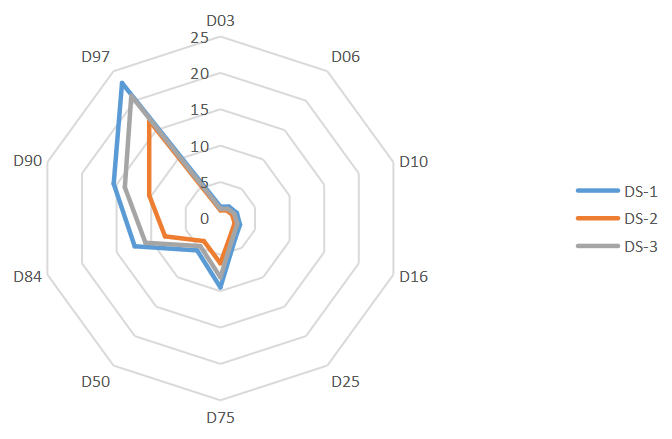

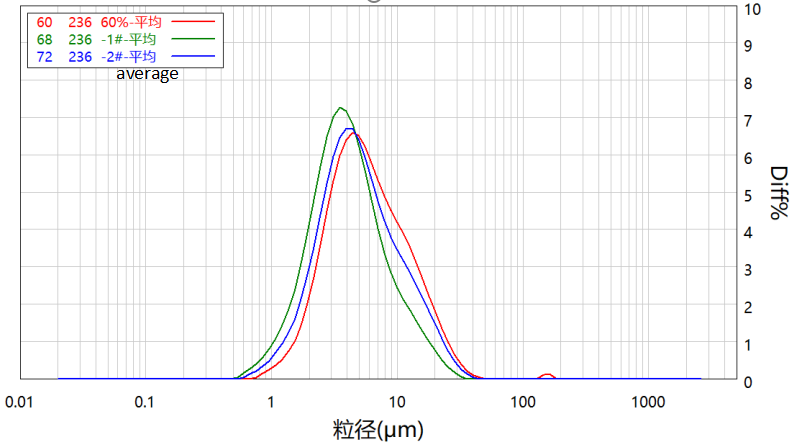

The experiment evaluated the effect of two dispersants added at 2% on particle size.

| Parameter | DS-1 /μm | DS-2/μm | DS-3/μm | |

| D03 | 1.617 | 1.113 | 1.315 | |

| D06 | 2.003 | 1.398 | 1.663 | |

| D10 | 2.382 | 1.696 | 2.012 | |

| D16 | 2.832 | 2.059 | 2.440 | |

| D25 | 3.449 | 2.527 | 3.000 | |

| D75 | 9.479 | 6.169 | 8.089 | |

| D50 | 5.437 | 3.859 | 4.709 | |

| D84 | 12.39 | 7.998 | 10.83 | |

| D90 | 15.42 | 10.29 | 13.81 | |

| D97 | 23.00 | 16.50 | 20.84 | |

1.3 Silicone high temperature coating performance

| NO. | Raw material | Dosage/% | Process |

| 1 | Silicone resin M-02 | 50 | |

| 2 | Dispersant DS-2130 | 1.5 | |

| 3 | Glass powder 33802 | 15 | Disperse for 15 minutes |

| 4 | Wetting agent UL-5124 | 0.2 | |

| 5 | Defoamer F-2561 | 0.2 | |

| 6 | Iron red paste 50% | 8 | Disperse for 5 minutes |

| 7 | Adhesion promoter D6600 | 0.2 | |

| 8 | Anti-flash rust agent 2062 | 0.4 | |

| 9 | Thickener HEC | 0.3 | Disperse for 5 minutes |

Summary

With the deepening of research on dispersants, the mechanism and effect of some hyperdispersants have been continuously discovered, and their applications in the special high-temperature coating industry are becoming more and more extensive.

This paper uses dispersants to prepare PTFE wax slurry, which can be well applied to aqueous silicone high-temperature coatings. The experimental results show that PTFE particles are evenly distributed in the coating with the dispersant and aggregated with silicone polymers, which has the effect of enhancing the anti-friction of the coating.

Related brands and products

-

Coating Additives

As an excellent supplier of coating additives, we provide a variety of additives for construction, automotive, wood, industrial and ink applications

-

Wood coatings

OSiC always pays attention to the needs of each customer, and develops carmot series of organosilicon additives,

-

Industrial coatings

The improvement of water-based coatings' performance also enables them to be used in a wider range of applic

-

Architectural coatings

OSiC provides a wide range of sustainable solutions for architectural coatings customers OSiC provides a variety

-

Automotive Coatings

OSiC provides additive solutions for waterborne and solvent based automotive OEM coatings, such as primer, single-l

-

Water based ink

The ink industry is one of the growing markets in the world, especially due to the growing printing ink market