RETé UR-5988: Low-K/Low-defect Silicone Stabilizer in Refrigerator Application

Cao Jia

Liu Qiang

OSiC Performance Materials

Urethane Additives

No.1218, Songsheng Road

201600 Shanghai

China

Polyurethane rigid foam is a material formed by foaming polyether or polyester polyol with isocyanate, chain extender or crosslinking agent such as water, polyamine or small molecule polyol under the action of catalyst. It has the advantages of light weight, high strength, good dimensional stability, and high mechanical strength. At the same time, rigid polyurethane foam has excellent thermal insulation performance, and is one of the materials with the lowest thermal conductivity. It is mainly used in refrigerators, building panels, pipelines and other fields, and is known as the ideal insulation material for achieving 65 % energy saving.

With the increasingly stringent requirements of environmental laws and regulations, as well as the increasing energy efficiency standards of household appliances, the requirements for polyurethane rigid foam products and energy efficiency in the refrigerator industry are gradually increasing. It is particularly important to have better thermal conductivity and lower overall energy consumption level. The overall industry development is moving towards the direction of high efficiency, energy saving, safety and environmental protection.

Aiming at the current situation of the refrigerator industry, by comparing with a silicone surfactant Sample -B commonly used in the market, OSIC has developed a new silicone surfactant RETé UR-5988 which can reduce the overall surface defects and the thermal conductivity, thus reduce the energy consumption of the refrigerator.

1. Experimental section

1.1 Main Components

Polyether polyol A, OH Value: 430~470 mg KOH/g, Polyether polyol B, OH Value: 310~370 mg KOH/g, Polyether polyol C, OH Value: 90~110 mg KOH/g, JURONG NINGWU NEW MATERIAL CO.,LTD;

PC-5、PC-8、PC-41, JIANGSU OSIC PERFORMANCE MATERIALS CO.,LTD;

Silicone surfactant UR-5988,JIANGSU OSIC PERFORMANCE MATERIALS CO.,LTD;

Silicone surfactant Sample-B from the market;

Blowing agent (C-PENTANE),FOSHAN MEILONG CYCLOPENTANE CHEMICAL CO.,LTD;

HFC-245fa,Honeywell InternationaL CO.,LTD;

PM-200,Wanhua Chemical Group Co.,Ltd. above materials are industrial grades.

1.2 INSTRUMENT AND EQUIPMENT

Fox-200 thermal conductivity meter, Laser Comp, USA;High speed mixer, PENDRAULIK, Germany; L-shape mold,climbing mold,customized;JSM-7600F scanning electron microscope,Japan Electronics Co., Ltd;HY-0580 multi-purpose tester,Shanghai Hengyi Precision Instrument Co., Ltd.

1.3Basic formula for Refrigerator evaluation and foam preparation method

| Raw Material | Pphp |

| Mixed polyether polyol | 100 |

| Silicone surfactant | 2 |

| PC-5 | 0.1-0.2 |

| PC-8 | 1-1.2 |

| PC-41 | 0.4-0.5 |

| Water | 2 |

| CP/CP+245fa | 14-18 |

| Crude MDI | 120-125 |

Use one step method to mix the raw materials according to the basic formula except crude MDI, pour crude MDI into the polyol blends at a certain rate, stir at high speed (3000 r/min) for 10s, then pour all materials into the mold and wait it become polyurethane rigid foam. Cure the foam at room temperature for 24 hours, then test its physical properties.

1.4 Test Standard

Test foam density as per GB/T 6343-2009 standard. Test foam thermal conductivity as per GB/T 10295-2009 standard. Test foam compression strength as per GB/T 8813-2008 standard; Test foam size stability as per GB/T 8811-2008 standard.

Flowability: pour the foaming fluid into a specific foaming tube, seal the bottom, so that the foam will only climb up. Measure the height H (CM) and the weight m (g) of foam in the tube, the ratio of height and weight (H/m) indicates the flow index (cm/g).

2. Result and Discussion

2.1 The compatibility and SEM characteristics of UF-5988 in the system

Compatibility of the system material is an important indicator to judge whether silicone surfactant is stable in the system. Mix UR-5988 with two types of blowing agent respectively, CP and CP / 245fa, place the system material at room temperature for 6 months. The mixtures become well-distributed and clear without stratification, which indicates that UR-5988 has good compatibility in refrigerator system.

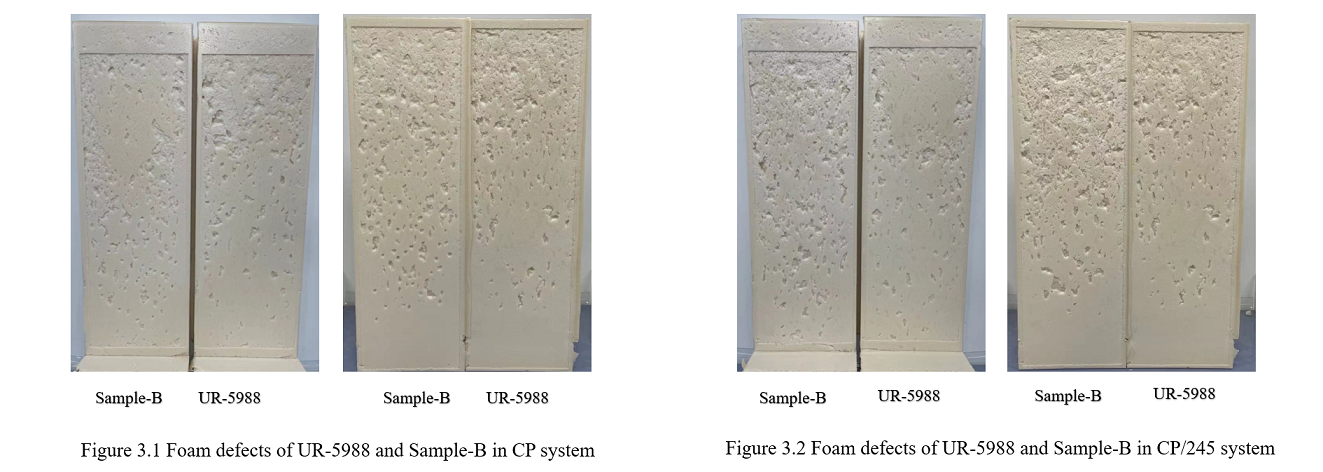

Figure 2 is a scanning electron microscope image obtained by UR-5988 from system CP and CP/245fa. It can be seen from the diagram that the size of the foams is relatively uniform, indicates that the foams obtained are fine and smooth.

2.2 Flowability Index

The formation of thermal insulation materials such as refrigerator, insulation boards and pipes requires good flowability of the system material, flowability matters on the performance of polyurethane rigid foam.

Under the CP and CP/245fa systems, we test the flowability index of UR-5988 and Sample-B by using climb experiment, as shown in Table 1:

| Foaming system Silicone surfactant | CP | CP+245fa |

| UR-5988 | 1.25 | 1.31 |

| Sample-B | 1.26 | 1.32 |

Through table 1, we know that the flowability index of UR-5988 in CP and CP/245fa systems is basically as same as that of the market product Sample-B, they are considered that they are at the same level.

2.3 Foam Surface Performance

Foam surface performance is one of the main indicators of polyurethane foam. It affects the performance of rigid foam at a certain extent. The foam surface defects difference between the foams made by UR-5988 and Sample-B in CP and CP/245fa system are shown in Figure 3:

It can be seen from Figure 3 that in CP and CP / 245fa systems, the surface voids of the foam made by UR-5988 are less than that of Sample-B, indicates that the surface performance of UR-5988 is better than that of Sample-B.

2.4 Thermal Conductivity

Thermal conductivity is an important indicator to measure the thermal insulation performance of materials, which directly affects the thermal insulation effect and energy consumption of the refrigerator, insulation boards and other finished products, It mainly comes from three heat transmission control processes: polymer heat conduction, gas heat conduction and radiation heat conduction. Gas heat conduction mainly comes from blowing agent. With the same amount and same type of blowing agent, it is possible to make cell structure finer by changing silicone surfactant, because silicone surfactant helps on emulsification, improves foam density and cell structure, subsequently reducing thermal conductivity. Table 2 shows the thermal conductivity of the foam made by UR-5988 and Sample-B in the systems of CP and CP/245fa [unit: MW/ (m k)]:

| Foam conductivity Silicone surfactant | CP | CP+245fa |

| UR-5988 | 21.60 | 21.46 |

| Sample-B | 21.80 | 21.58 |

It can be seen from table 2 that in CP system, the thermal conductivity of the foam made by UR-5988 is 21.60 MW / (m · K), which is 0.2 MW / (m · K) lower than that of Sample-B; In CP / 245fa system, the thermal conductivity of the foam made by UR-5988 is 21.46 MW / (m · K), which is 0.12 MW / (m · K) lower than that of sample-b.

In conclusion, the thermal conductivity of the foam made by UR-5988 is lower than that of Sample-B in both CP and CP / 245fa systems, and the result is quite obvious.

2.5 Compression Strength

Compressive strength is one of the important indicators to measure the mechanical properties of the material. The greater the compressive strength, the greater the ability of materials to resist compressive load without failure, the more stable the material structure is, and because of the growth of polyurethane rigid foam in a certain direction, the compression strength of in parallel and vertical direction are different, the smaller the difference, the more stable the foam is.

| Silicone surfactant | Compression strength/kPa | |||||

| CP | CP+245fa | |||||

| Parallel | Vertical | Anisotropy | Parallel | Vertical | Anisotropy | |

| UR-5988 | 162 | 154 | 0.95 | 181 | 168 | 0.93 |

| Sample-B | 166 | 154 | 0.93 | 179 | 169 | 0.94 |

It can be learnt from Figure 3 that the foam made by UR-5988 and Sample-B in CP and CP/245fa system acquires almost same results in compression strength, not much difference observed.

2.6 Dimensional Stability

Dimensional stability reflects the shelf life of polyurethane rigid foam, bad foam dimensional stability will result into the problems of foam shrinkage and falling-off. Therefore, dimensional stability is an important property of rigid polyurethane foam.

Table 4 is a comparison of foam dimensional stability between the foam made by UR-5988 and Sample-B in CP and CP/245fa systems:

| Silicone surfactant | CP | CP+245fa | ||||

| Dimensional stability(48h、-30 ℃)/% | Dimensional stability(48h、100 ℃)/% | |||||

| Length | Width | Height | Length | Width | Height | |

| UR-5988 | -0.20 | -0.11 | -0.09 | -0.39 | -0.26 | -0.33 |

| Sample-B | -0.18 | -0.16 | -0.07 | -0.28 | -0.37 | -0.41 |

It can be seen from Figure 4 that the foam made by UR-5988 and Sample-B in CP and CP/245fa systems have basically same value on dimensional stability separately on the length, width, height. The difference is less than 1%, no obvious shrinkage and obvious difference observed.

3. Conclusion

Under the system CP and CP/245fa, we compared flowability, thermal conductivity, compression strength, dimensional stability and surface defects of the foam made by UR-5988, a new product of OSIC, and Sample – B, results show as below:

(1) the size stability, flowability and compression strength of the foam made by UR-5988 and Sample-B are basically the same, and there is no great difference.

(2) the thermal conductivity of the foam made by UR-5988 is lower than that of Sample-B, and the thermal insulation effect is better.

(3) the surface defects of the foams made by UR-5988 are less than those of Sample-B.

BIOGRAPHIES

Cao Jia

Born in 1984, graduated with a master's degree from Donghua University. From 2010 to 2020, Cao worked at BASF Polyurethane Specialty Products and Covestro Polyurethane, responsible for polyurethane rigid foam technical services(household appliances and building materials) . Cao joined OSiC in 2020 as a technical sales manager, in charge of polyurethane rigid foam technical support and key customer sales services.

Liu Qiang

Master of Analytical Chemistry from Jiangsu University, Intermediate Engineer, Intellectual Property Engineer, and talents in shortage of key industries in Suzhou. Liu joined OSiC in 2015 as R&D engineer. He has been engaged in the research and development of polyurethane additives for polyurethane rigid foam and has rich project management experience.