NOVAX EC-240: Improve the compression performance of flexible polyurethane foam

Wan Qihua

OSiC Performance Materials

Urethane Additives

No.1218, Songsheng Road

201600 Shanghai

China

One-third of one 's life is spent in bed. The quality of mattress plays a decisive role in the quality of sleep. With the continuous improvement of living standards, people have higher requirements for the quality of life. Before the 1950s, mattresses were mainly filled with cotton and natural fibers. With the invention and maturity of polyurethane technology, mattress manufacturers began to use polyurethane foam as a substitute for mattress cushions.

Polyurethane flexible foam has an open porous structure with different diameters and mixed distributions. It can produce different rebound forces when subjected to pressure from the human body. Therefore, the biggest feature of polyurethane soft foam is that it has a very good rebound, and it can discharge the body ' s heat through the open pore structure,making night sleep more comfortable. The use of environmentally friendly water-based adhesives to combine polyurethane foam can achieve a comfort level similar to that of natural latex foam.

In order to reduce transportation costs, the polyurethane flexible foam needs to be compressed for long-distance transportation, and the volume of the mattress becomes smaller after compression, which saves storage space. In recent years, shipping prices have become higher and higher, and the cost pressures on mattress manufacturers have also increased. Especially in the past two years, due to the ravages of the new crown virus, the shipping market has been greatly affected. The shipping time has increased, and the time for mattresses to stay in the port has become longer. Therefore, higher compression performance requirements have been put forward for the flexible polyurethane foam.

OSiC launched the NOVAX EC-240 polyurethane additive, which can significantly improve the compression performance of flexible polyurethane foam, solve the problem of long-term storage and transportation after compression of the foam, help customers solve the return caused by the unrecoverable compression, and reduce the risk of compression foam waste rate.

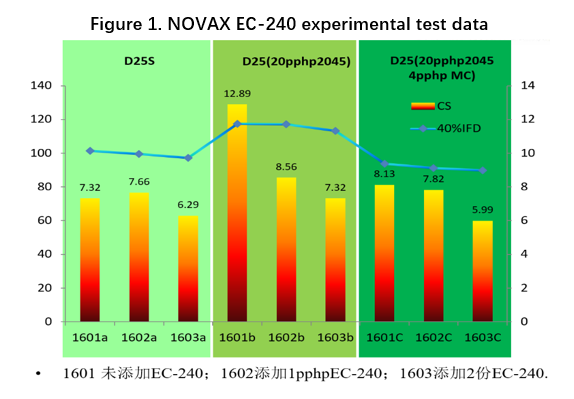

As shown in Fig. 1, two parts of NOVAX EC-240 were added to the standard 25 - density formula, and the compression set decreased by 14 %. In the 25 density formula containing 20 phr POP(white oil), the compression set decreased by 43.2 % with 2 phr EC-240. Adding 2 phr EC-240 to the 25 density formula containing 20 phr POP and 2 phr MC is also effective, and the compression set decreases by 26.3 %.

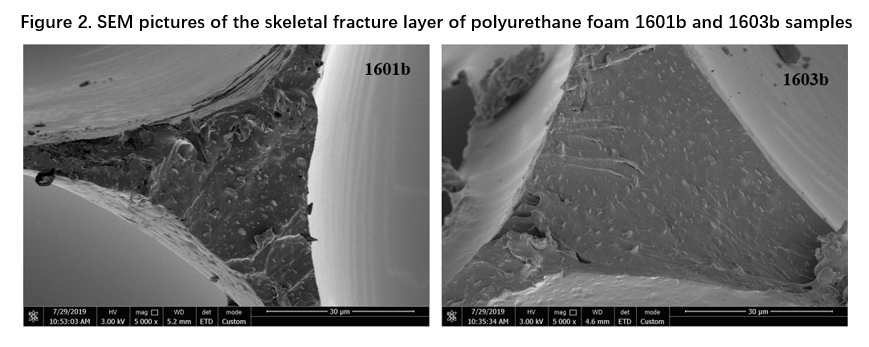

NOVAX EC-240 can improve the opening performance of foam and has a certain foam stability. In the production process of polyurethane foam, the organic particles in POP are easy to agglomerate due to aggregation or uneven dispersion in the formation of foam skeleton, resulting in damage or destruction of foam skeleton. By observing the cross section of skeleton fracture layer, we can find that the cross section is smoother after adding EC-240 ( Fig. 2 ).

Compression set is an important index to evaluate the quality of foam. During the use of foam, the irreversible slip of polymer chain during compression and release causes the loss of energy and recovery ability, and the foam produces compressive deformation. NOVAX EC-240 can increase the cell openning of foam and improve the integrity of foam skeleton, thereby improving the compression performance of the flexible polyurethane foam.

BIOGRAPHIES

Wan Qihua

Born in 1987,master of Nanchang University. Wan studied the design, synthesis and application of organic small molecule fluorescent probes in school. He joined OSiC in 2013 as R & D engineer, engaged in the development and application of various additives related to polyurethane flexible foam, including catalysts, surfactants and other functional additives, and special foams development.

OSiC Performance Materials

Urethane Additives

No.1218, Songsheng Road

201600 Shanghai

China

One-third of one 's life is spent in bed. The quality of mattress plays a decisive role in the quality of sleep. With the continuous improvement of living standards, people have higher requirements for the quality of life. Before the 1950s, mattresses were mainly filled with cotton and natural fibers. With the invention and maturity of polyurethane technology, mattress manufacturers began to use polyurethane foam as a substitute for mattress cushions.

Polyurethane flexible foam has an open porous structure with different diameters and mixed distributions. It can produce different rebound forces when subjected to pressure from the human body. Therefore, the biggest feature of polyurethane soft foam is that it has a very good rebound, and it can discharge the body ' s heat through the open pore structure,making night sleep more comfortable. The use of environmentally friendly water-based adhesives to combine polyurethane foam can achieve a comfort level similar to that of natural latex foam.

In order to reduce transportation costs, the polyurethane flexible foam needs to be compressed for long-distance transportation, and the volume of the mattress becomes smaller after compression, which saves storage space. In recent years, shipping prices have become higher and higher, and the cost pressures on mattress manufacturers have also increased. Especially in the past two years, due to the ravages of the new crown virus, the shipping market has been greatly affected. The shipping time has increased, and the time for mattresses to stay in the port has become longer. Therefore, higher compression performance requirements have been put forward for the flexible polyurethane foam.

OSiC launched the NOVAX EC-240 polyurethane additive, which can significantly improve the compression performance of flexible polyurethane foam, solve the problem of long-term storage and transportation after compression of the foam, help customers solve the return caused by the unrecoverable compression, and reduce the risk of compression foam waste rate.

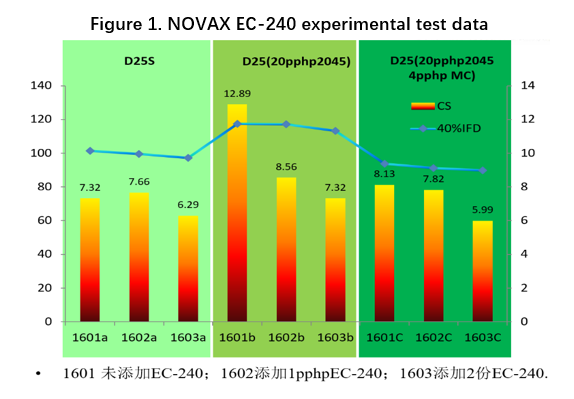

As shown in Fig. 1, two parts of NOVAX EC-240 were added to the standard 25 - density formula, and the compression set decreased by 14 %. In the 25 density formula containing 20 phr POP(white oil), the compression set decreased by 43.2 % with 2 phr EC-240. Adding 2 phr EC-240 to the 25 density formula containing 20 phr POP and 2 phr MC is also effective, and the compression set decreases by 26.3 %.

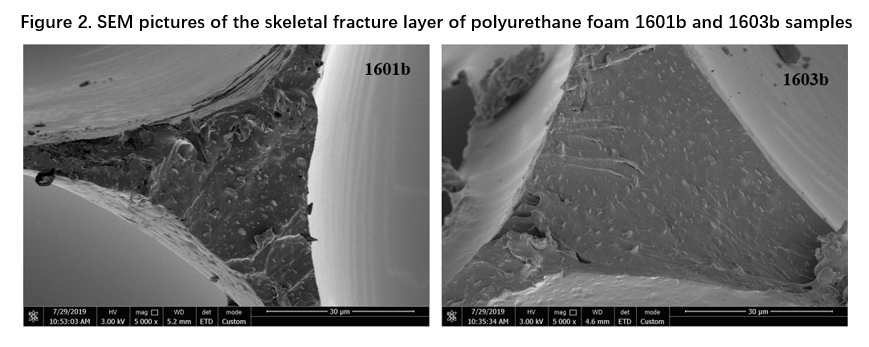

NOVAX EC-240 can improve the opening performance of foam and has a certain foam stability. In the production process of polyurethane foam, the organic particles in POP are easy to agglomerate due to aggregation or uneven dispersion in the formation of foam skeleton, resulting in damage or destruction of foam skeleton. By observing the cross section of skeleton fracture layer, we can find that the cross section is smoother after adding EC-240 ( Fig. 2 ).

Compression set is an important index to evaluate the quality of foam. During the use of foam, the irreversible slip of polymer chain during compression and release causes the loss of energy and recovery ability, and the foam produces compressive deformation. NOVAX EC-240 can increase the cell openning of foam and improve the integrity of foam skeleton, thereby improving the compression performance of the flexible polyurethane foam.

BIOGRAPHIES

Wan Qihua

Born in 1987,master of Nanchang University. Wan studied the design, synthesis and application of organic small molecule fluorescent probes in school. He joined OSiC in 2013 as R & D engineer, engaged in the development and application of various additives related to polyurethane flexible foam, including catalysts, surfactants and other functional additives, and special foams development.