Ultra smooth silicone oil emulsion ARATEX L-618

OSiC has launched ARATEX L-618, an ultra-smooth silicone oil emulsion with a macromolecular structure.

This product adopts a unique emulsion polymerization technology, the molecular weight of silicone oil and the particle diameter of the emulsion are relatively large, so after adopting softener, most of the silicone oil remains on the surface of the fabric. When drying and setting, the active functional group components will curing into elastic film after the water evaporation, forming a kind of special touch which is both smooth and elastic. ARATEX L-618 is usually used with other block silicone oils or added into other softeners as smooth and elastic components, so that it can be made to have a supple and smooth touch style.

01/Test content and method

Cotton woven fabric padding process

| 1# block silicone oil emulsion L-3307:20g/L |

| 2# block silicone oil emulsion L-3307:10g/L ARATEX L-618:5g/L |

02/ Results

| No. Supple Smooth Elastic |

| 1# 4 4 4 |

| 2# 4.5 5 4.5 |

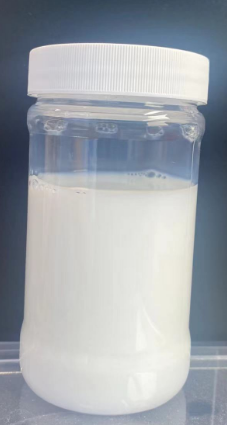

Main physical characteristics of ARATEX L-618

| Test item Unit Typical data |

| Appearance Milky white liquid |

| Viscosity cst <50 |

| Solids concentration % 29-34 |

| Ion type Cationic |